Behind the scenes

-

March 06, 2025

From Sheffield to the World: Inside the making of the PCL AIRFORCE MK4 Tyre Inflator

The PCL AIRFORCE MK4 tyre inflator is the result of decades of innovation, following the MK2 introduced in 1945 and the MK3 that followed in 1993. Creating a PCL AIRFORCE MK4 tyre inflator involves a detailed, precision-driven process to ensure each inflator meets our high standards. From sourcing components to the final test, every step is carefully executed. Here's a step-by-step look at how the PCL AIRFORCE MK4 is made in our factory in Sheffield:

Step 1: Sourcing and preparing components

The journey begins with acquiring the necessary

-

February 05, 2025

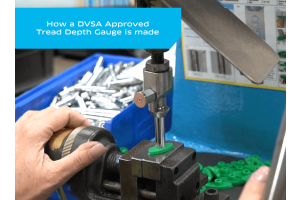

How a PCL DVSA Approved Tread Depth Gauge is made

At PCL, we have been manufacturing our DVSA MOT Test approved tread depth gauge for over 70 years from our factory in Sheffield. Our gauges are widely used around the world, found in glove boxes, garages, and tyre shops, where they serve as a vital tool for ensuring tyre safety. These gauges play a crucial role in measuring tyre tread depth, helping drivers maintain proper tyre conditions and meet legal requirements.

But have you ever wondered how a PCL DVSA approved tread depth gauge is made? Let’s take you through the step-by-step process behind the manufacture of this essential tool.

Step 1: Machine and quality check the components

The first stage in the process takes place in our machine shop, where the individual components of the tread depth gauge are precisely

-

January 16, 2025

How a PCL Coupling is made: A journey from precision machining to quality assurance

At PCL, we take pride in every coupling we produce, ensuring it meets the highest standards of quality and performance. From the initial machining of components to the final testing before shipment, every step is carefully crafted in our factory in Sheffield, UK. In this post, we’ll take you through the process of how a PCL coupling is made - from the machine shop to your hands.

Step 1: Machining the components

The journey begins in our state-of-the-art machine shop, right here in Sheffield. Each component of the coupling is carefully machined to the highest standards. Our skilled machinists use precision equipment to create the essential parts of each coupling. This attention to detail ensures that every component is made to fit